Flight

Controls System Presentation

In

conventional aircraft, the movement of the control column is transferred along

cables and pulleys, until it reaches the control surface to be moved.

In

the A320 family, the cables and pulleys have been replaced by electrical wires.

This

has the advantage of saving weight on the aircraft.

However,

there are even greater advantages as the video clip will demonstrate.

The

electrical signals, created by sidestick movement, travel through flight

control computers before being passed to

the surface hydraulic actuators, also named servo controls.

The

pilots use the sidesticks to fly the A/C.

Computers

interpret the pilot’s inputs and move the flight controls surfaces as necessary

preventing excessive maneuvers and flight outside the safe flight envelope.

Pilot’s

input is converted into an A/C control objective.

No

direct relationship between stick and surface.

The

A/C is servo looped.

This

has advantages over conventional systems, it:

- makes the aircraft extremely stable,

- enhances safety,

- reduces the pilot’s workload.

- makes the aircraft extremely stable,

- enhances safety,

- reduces the pilot’s workload.

The

movements of the flight control surfaces are managed by seven computers. These

are:

- two ELevator and Aileron Computers (ELAC),

- three Spoiler and Elevator Computers (SEC),

- two Flight Augmentation Computers (FAC), which manage the rudder movements.

- two ELevator and Aileron Computers (ELAC),

- three Spoiler and Elevator Computers (SEC),

- two Flight Augmentation Computers (FAC), which manage the rudder movements.

The

flight control system is designed to incorporate several redundancy and safety

concepts:

- Each computer is able to control the aircraft in flight.

- Each computer is divided into two physical units which are programmed in two different software languages.

- Segregated power supply, control source and signaling lanes.

- Extensive monitoring within each computer allows detection of failures in controls, computers and sensors.

- With the basic configuration, no single failure (computer, electrical system, hydraulic system, sensors …) will cause a degradation of the normal functions.

- Each computer is able to control the aircraft in flight.

- Each computer is divided into two physical units which are programmed in two different software languages.

- Segregated power supply, control source and signaling lanes.

- Extensive monitoring within each computer allows detection of failures in controls, computers and sensors.

- With the basic configuration, no single failure (computer, electrical system, hydraulic system, sensors …) will cause a degradation of the normal functions.

Two

Flight Control Data Concentrators (FCDCs) are installed.

They

receive data from ELAC and SEC computers for indication, recording, and

maintenance purposes.

The

FCDC stores the maintenance data and delivers failure indications (e g.stored

failures, failure history, trouble shooting guidance, etc ...)

as well as failed LRUs to the Centralized Fault Display Interface Unit (CFDIU).

The

FCDC’s interface with ECAM system (surface position, computer status, surface

status) and interface with the DFDR (flying parameter recording).

However,

the data from both FACs is directly sent to the EIS.

Three

independent hydraulic systems are used to power all the flight control

surfaces.

The

flight control system incorporates:

•

Ailerons:

Each aileron is powered by two servo controls from independent

hydraulic systems.

In normal operation, one servo control is active through the ELAC,

the other one being damped.

Surface position indication is displayed on the ECAM display unit.

Each aileron is powered by two servo controls from independent

hydraulic systems.

In normal operation, one servo control is active through the ELAC,

the other one being damped.

Surface position indication is displayed on the ECAM display unit.

•

Elevators:

Each

elevator is actuated by two independent hydraulic servo controls.

In normal operation one servo control is active through the ELAC

(SEC in backup), the other is damped.

In normal operation one servo control is active through the ELAC

(SEC in backup), the other is damped.

In

the event of total electrical control loss, the servo controls

are

automatically switched to a centering mode and will hold the surface

in the neutral position.

automatically switched to a centering mode and will hold the surface

in the neutral position.

Surface

position indication is displayed on the ECAM display unit.

• A Trimmable

Horizontal Stabilizer (THS) for pitch trim:

The

THS is actuated by a fail-safe ball screw-jack driven by two

independently supplied hydraulic motors.

independently supplied hydraulic motors.

Manual

control of the THS is achieved through the interconnected

handwheels located on the center pedestal.

handwheels located on the center pedestal.

On

the ground, the THS setting must be performed through the

manual control.

manual control.

As

soon as the aircraft is airborne, the THS automatically engages

in

electrical control mode .

electrical control mode .

The

mechanical control can override the electrical control (in case of

auto trim runaway).

auto trim runaway).

Automatic

pitch trim is achieved with the THS through the ELAC.

When

the auto trim function is engaged, any movement of the

elevators will be followed by a THS movement in order to align the

surfaces for drag reduction (fuel saving).

elevators will be followed by a THS movement in order to align the

surfaces for drag reduction (fuel saving).

The

THS position indication is displayed on

the ECAM display unit

and is also indicated in degrees on a scale adjacent to each trim

handwheel.

and is also indicated in degrees on a scale adjacent to each trim

handwheel.

•A

rudder:

The

single-piece rudder is actuated by three independently supplied

hydraulic servo-controls mechanically signaled from the pedals and

the yaw damper actuators.

hydraulic servo-controls mechanically signaled from the pedals and

the yaw damper actuators.

The

rudder position indication is displayed on the ECAM display unit.

•And

finally, ground spoilers/speed brakes:

Each

spoiler is driven by a single servo control through one of the

three SECs.

three SECs.

For

redundancy, the hydraulic supply from the three systems

is

distributed among the spoilers servocontrols.

distributed among the spoilers servocontrols.

In

case of failure detected by the SEC, the corresponding spoiler

retracts automatically and is held in that position.

retracts automatically and is held in that position.

The

spoiler position indication is displayed on the ECAM display unit.

Now

let’s introduce the ECAM F/CTL page.

You

can see that all the flight control surfaces we have talked about are

displayed. We will now see them in more detail.

The

movements of both ailerons and both elevators are symbolized by a green index

moving in front of a white scale.

The servocontrol status, displayed on the side of the

white scale, will become amber when the corresponding actuator is not available

(hydraulic low pressure, electrical control failure, computer failure, etc).

•

Ailerons:

The

ailerons are shown in neutral position.

NOTE:

The indication below corresponds to the new neutral position when the flaps are

extended (aileron droop automatic function).

•

Elevators:

In

case of elevator failure, the deflection of the remaining elevator is limited

by the computer to avoid excessive asymmetrical loads on the horizontal tailplane

or rear fuselage.

The

green rudder symbol is used as an index to display the movements of the rudder on a white scale.

The servocontrol status is displayed on top of the rudder

indication.

The

rudder trim is indicated by a small blue line below the scale.

When

used, the rudder trim will move the neutral point of the rudder surface and

change the rudder pedals position.

The

hydraulic systems which actuate each control surface are indicated on the ECAM

F/CTL page by G, B and Y.

For

example, the rudder is powered by the green, blue and yellow hydraulic systems.

Note

that the rudder and the pedal deflections are limited via a rudder travel

limiter at high speed.

Rudder

travel is limited as a function of airspeed.

The

FACs control electric motors coupled with a variable stop mechanism.

The

high speed position is indicated by small white ticks on the rudder scale.

The

PITCH TRIM position is indicated by THS deflection in degrees up or down.

The

pitch trim hydraulic motor status is displayed on top of the THS position

indication.

The

spoilers have several functions:

-

Speed brakes use the 3 central surfaces.

On the ECAM F/CTL page, the spoiler extended position is indicated

by small arrows. This is the case for the speed brakes.

On the ECAM F/CTL page, the spoiler extended position is indicated

by small arrows. This is the case for the speed brakes.

-

Speed brakes are used to decrease the aircraft speed and to

increase the rate of descent.

increase the rate of descent.

Speed

brakes inhibition:

The computers will automatically retract the speed brakes or keep

them retracted in the following conditions:

The computers will automatically retract the speed brakes or keep

them retracted in the following conditions:

• Aircraft in high Angle Of Attack

condition.

• Flaps full configuration selected

(landing).

• Computer failure.

• Roll

spoilers:

To

complement the ailerons action, the roll spoilers are deployed automatically by

the computers on the same side as the aileron which is deflected upward (they

remain retracted on the other wing) and proportionally to this aileron

deflection.

The

computers are able to mix the speed brakes function with the roll spoilers.

Look

at the video carefully.

Roll

control uses the four outer surfaces.

On

the video, look at the left spoilers as they deploy, then at the right ones as

the wings are leveled.

Ground

spoilers use all surfaces at their maximum deflection.

The

ground spoilers are used to maintain the aircraft on the ground

(ground lift dumper) and to reduce the speed.

(ground lift dumper) and to reduce the speed.

Ground

spoilers will remain extended during bounces.

Ground

spoilers are automatically extended after touchdown or in

case of rejected take off when specific ground conditions are fulfilled.

case of rejected take off when specific ground conditions are fulfilled.

Pre-selections

have to be made through the speedbrake control lever

located on the center pedestal.

located on the center pedestal.

They

will retract when deselected with the speedbrake control lever

or one engine thrust lever is advanced above idle position.

or one engine thrust lever is advanced above idle position.

On

the video, watch all the spoilers deploy at touchdown.

The

status of the ELACs and SECs is indicated on the ECAM F/CTL page. The other

computers are not displayed.

Pilots

control pitch and roll through two side sticks.

The

side stick advantages are:

- improved crew interface,

- system simplification,

- weight and room saving.

- improved crew interface,

- system simplification,

- weight and room saving.

Each

side stick sends independent electrical signals to the flight controls

computers.

When

both side sticks are used at the same time, their inputs are algebraically

added by the computers.

When

the auto pilot is engaged both side sticks are locked in the neutral position

by a solenoid system.

Each

side stick is fitted with a red pushbutton which is used for:

- Autopilot manual disconnection.

- Deactivation of the other stick when this pushbutton is kept pressed to take the priority in case of crew incapacitance or during flight training.

- Autopilot manual disconnection.

- Deactivation of the other stick when this pushbutton is kept pressed to take the priority in case of crew incapacitance or during flight training.

For

rigging purposes, the side stick can be held in neutral position by a single

rigging pin (aileron, spoiler, elevator servo control adjustments).

There

are associated side stick priority lights.

Manual

control of the THS is achieved through the interconnected handwheels

located on the center pedestal.

The

trim position is indicated in degrees on a scale adjacent to each trim wheel.

The

normal range is marked by a green band.

NOTE:

Crew action on the pitch trim wheel does not disconnect the ELACs, they remain

synchronized with the manually selected position.

Following

touch down, the pitch trim is automatically reset to zero.

When the pitch trim is engaged in

electrical mode, a feedback movement is sent to the wheels via the mechanical

channel

There

are two sets of conventional rudder pedals.

These

pedals are adjustable for pilot comfort.

The

two sets of pedals are mechanically interconnected.

When

the autopilot is engaged, the rudder pedals are locked in neutral

position.

A RUD

TRIM panel is located on the pedestal.

Manual

trim orders are received from a switch located on the center pedestal.

An

automatic reset function is initiated through a pushbutton switch and allows

the trim position to be nulled.

The

position indicator displays the rudder trim direction (L or R) and value.

The

rudder trim rotary switch is not active when the autopilot is engaged as the

rudder trim is controlled by the autopilot system.

A

speed brake lever is located on the left side of the pedestal.

To

select speed brakes, the lever has to be pushed down and set to the required

position.

To

arm the ground spoilers the lever must be pulled up when in retracted position.

Upon

ground spoiler deployment, there is no movement of the lever, a it is an

electrical control.

In

addition, there are two panels, located on the overhead panel, to control the flight control computers.

Switching

OFF then ON resets the corresponding computer.

The

ELAC 1 and SEC 1 are normally supplied by the ESSential BUS

but can be supplied by the HOT BUS in case of electrical failure.

but can be supplied by the HOT BUS in case of electrical failure.

Now,

we will introduce the lift augmentation devices.

High-lift

control is achieved on each wing by:

- five leading edge slats,

- two trailing edge flaps,

- one aileron (aileron droop function).

- five leading edge slats,

- two trailing edge flaps,

- one aileron (aileron droop function).

Slats

and flaps are driven through similar hydromechanical systems consisting of:

- Power Control Units (PCU),

- differential gearboxes and torque shafts,

- rotary actuators.

- Power Control Units (PCU),

- differential gearboxes and torque shafts,

- rotary actuators.

There

are 5 slats on each leading edge ...

… and

2 flaps on each trailing edge.

NOTE:

the A321 has double slotted flaps.

The

slats and flaps Power Control Units are hydraulically actuated.

They

are electrically controlled via two Slat

Flap Control Computers (SFCC).

The

SFCCs monitor the slats and flaps operation through Position Pick-off Units

(PPUs) located on the PCUs and at the end of the transmission torque shafts.

The

slats and flaps operate with protection functions such as:

- asymmetry,

- runaway,

- overspeed,

- uncommanded movement.

- asymmetry,

- runaway,

- overspeed,

- uncommanded movement.

Each

SFCC has two channels, one for the flaps

and one for the slats.

Each

channel can drive its associated surfaces.

The

flaps and slats information is shown on the EWD.

The

System Data Acquisition Concentrators (SDACs) receive slat and flap positions

from feedback PPUs through SFCCs to

generate appropriate ECAM displays.

The

flap and slat positions are indicated by white dots. Here, the surfaces are

extended to the full position.

This

is the flap 0 indication. Notice there is no labeling with this setting.

The

flap lever, located on the right side of the pedestal, operates the slats and

flaps.

Before

selection of any position, the lever must be pulled out of the detend.

Moreover,

balks are provided at position 1 and 3 to avoid excessive flap/slat travel

demand by a single pilot action.

The

flap lever has the following positions: 0, 1, 2, 3 and FULL.

ELAC

1, SEC 1, FAC 1 and FCDC 1 are located in rack

83 VU.

ELAC

2, SEC 2, FAC 2 and FCDC 2 are located in rack

84 VU.

SFCC

1 is located in rack 85 VU.

SFCC

2 is located in rack 86 VU.

SEC 3

is located in rack 93 VU.

The

ELACs, SECs and SFCCs BITE memories can be read and tests

triggered on the MCDU through F/CTL key.

triggered on the MCDU through F/CTL key.

The

FACs send data to the CFDIU. Their BITE memories can be read

and tests triggered through the MCDU AFS menu.

and tests triggered through the MCDU AFS menu.

The

ELACs and SECs send data to the CFDIU through the FCDCs.

The

SFCCs send data directly to the CFDIU.

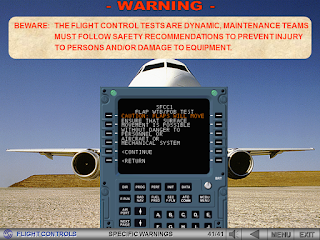

When you work on flight controls,

make sure that you obey all the AMM safety

procedures. This will prevent

injury to persons and /or damage to the

aircraft. Here is an overview of

main safety precautions relative to the

flight control system.

Make sure that the controls agree

with the position of the flight control surfaces

before you pressurize hydraulic

system.

Put safety devices and warning

notices in position before you start a task

on or near flight controls.

Make sure that the travel ranges of

the flight control surfaces are clear.

Movement of flight controls can

cause injury to persons and/or damage

to the aircraft.

WARNING: The flight control tests are dynamic.

Movement

of flight controls can cause injury to persons and/or

damage to the aircraft.

damage to the aircraft.

It was another joy to see your post about HVAC company this topic. . It is such an important topic and ignored by so many, even professionals. I thank you to help making people more aware of possible issues. Great stuff as usual...

ReplyDeleteThat blog was amazing, I am impressed with your thoughts. I got the best information from this site, It’s very useful to all and us. Thanks for sharing this post.

ReplyDeletetop split air conditioner in sharjah

Wonderful blog! I found it while surfing around on Yahoo News. Do you have any tips on how to get listed in Yahoo News? I've been trying for a while but I never seem to get there! mechanical engineering edmonton

ReplyDeleteRated Best Online PLC, SCADA, HMI, DCS, Panel Design, Servo, Industrial Automation training in Noida & offers hands on practical exposure with 100% placement support. Call us @9953489987 or 9711287737.

ReplyDeletenicee

ReplyDeleteuh4v2fr4dd

ReplyDeletegolden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

supreme outlet

golden goose outlet

golden goose outlet

golden goose outlet