A320 Series Hydraulic System Presentation

The A320 family has three independent hydraulic systems:

- green,

- yellow,

- and blue.

- yellow,

- and blue.

Normal

system operating pressure is 3000 psi.

Hydraulic

fluid cannot be transferred from one system to an another.

Each

system has its own hydraulic reservoir which is pressurized with air to prevent

pump cavitation.

The

green and yellow hydraulic systems are each pressurized by an engine driven

pump (EDP 1 and EDP 2).

The

yellow hydraulic system can also be pressurized by an electric pump.

It is

mainly used on ground for maintenance operations and cargo door operations.

A

Power Transfer Unit (PTU) enables the green system to be pressurized by the

yellow system and vice versa.

It

transfers the hydraulic power but does not transfer the hydraulic fluid.

Fire

shut-off valves are located between the reservoirs and the engine driven pumps.

They

isolate the systems in case of an engine fire.

The

blue hydraulic system is pressurized by an electric pump.

The

electric pump is an hydraulic system main pump.

It

starts running at first engine start up.

Blue

and yellow pumps are fully interchangeable.

In an

emergency the blue system can be pressurized by the Ram Air Turbine (RAT).

The

Ram Air Turbine is deployed automatically or manually. It pressurizes the blue

hyd. system at 2500 psi. It can be retracted on ground only, following a

specific maintenance procedure.

Each

hydraulic system delivers a constant pressure to the users.All the components we have talked about are displayed on the ECAM HYD page.

Let’s briefly review the basic system using the ECAM HYD page:

- the reservoirs,

- the fire shut-off valves,

...

- the

pumps,- the fire shut-off valves,

...

- the

RAT,

...

- the

PTU,...

- the

pressure indications.

The

fire shut-off valve handles electrically control the operation of the fire

shut-off valves.The controls for the components that we have introduced are located on the overhead hydraulic control panel.

Let’s

now go to the ECAM HYD page together with the hydraulic control panel.

Each

hydraulic engine pump is controlled by a p/bsw located on the overhead panel.Each hydraulic electrical pump is controlled by a p/bsw.

The RAT may be extended manually by using this guarded p/bsw.

The PTU is located in the main landing gear bay. The blue electric pump and the RAT are located in the blue hydraulic bay, whereas the blue reservoir is at the rear of the main landing gear. EDP 1 is fitted on the accessory gearbox.

The green reservoir is located in the main landing gear bay. The yellow reservoir and electric pump are located in the yellow hydraulic bay. EDP 2 is fitted on the accessory gearbox.

The blue electric pump starts automatically when any one of the engines operates due to an electric logic.

The PTU starts automatically thanks to its hydro-mechanical detection system in order to power the green or the yellow system from the powered side.

The RAT is deployed automatically in flight or on ground by activating the RAT MAN ON switch.

Two

deploy solenoids are available to extend the RAT.

The

hot battery bus supplies 28 VDC to the deploy solenoid 1 and battery No2 supplies 28 VDC to the deploy solenoid

2.

RAT CONTROL

On

ground, the RAT retraction is controlled from the RAT control panel located on

the blue servicing panel.

The RAT retraction is electrically controlled and hydraulically operated provided the blue hydraulic system is pressurized.

The RAT retraction is electrically controlled and hydraulically operated provided the blue hydraulic system is pressurized.

RAT INDICATING

On

the RAT control panel there are 3 indicator lights:

- a red light for retraction jack pressurization,

- a green light for RAT stowed,

- an amber light for RAT blades not aligned.

RESERVOIR FILLING CONTROL- a red light for retraction jack pressurization,

- a green light for RAT stowed,

- an amber light for RAT blades not aligned.

The

reservoir filling is controlled from the green service panel, by manually

operating the reservoir filling selector to direct the fluid from the external

filling source to the reservoir of the serviced system.

INDICATING

On

the green servicing control panel, the multiple reservoir quantity indicator

allows the selected reservoir to be monitored.

In

the hydraulic compartments, the reservoir level, the air pressurization and

accumulator nitrogen charge are monitored by direct reading gages for

maintenance checks.The long term periodic/unscheduled test functions of the hydraulic system are ensured by the following on board maintenance facilities.

The

MCDU is used for trouble shooting the monitored components through AFS, F/CTL,

INST and L/G systems.

The

leak measurement valve P/B’s are used on ground for maintenance operations

(leak measurement test).

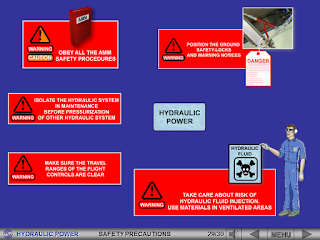

When you work on the hydraulic

system, make sure that you obey all the AMM safety procedures. This will

prevent injury to persons and/or damage to the aircraft. Here is an overview of

main safety precautions relative to the Hydraulic Power system.

Make sure that the ground

safety-locks and warning notices are in position.

Make sure that the hydraulic system

in maintenance is isolated before you pressurize the other hydraulic systems.

Make sure that the travel ranges of

the flight controls are clear. Movement of the flight controls can cause injury

to persons and/or damage to the aircraft.

Do not get hydraulic fluid or hot

gas from hydraulic reservoir on your body. Use protective clothing to prevent

risk of poisoning and burns. Use solvents, cleaning agents, sealants and other

special materials in a ventilated area. To prevent inadvertent breathing or

contact with your body, use applicable gloves, eye protection and face mask.

Install the RAT safety device

before working in the RAT extension area.

Do not push the RAT MAN ON switch.

The RAT will extend.

Make sure that the RAT travel range is

clear before you extend/retract the RAT.

Great Post on Hydraulics . Thanks for your information.

ReplyDeleteThanks for this. It's a good reviewer.

ReplyDeleteThank u. Easy to understand ✌🏻

ReplyDeleteIts a good reviewer thanks

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteUrgent need Female for egg donation with the sum of $500,000.00,whatsapp +91 9945317569

ReplyDeleteEmail: jainhospitalcare@gmail.com

this is very useful for every aviator

ReplyDeleteNice Post....

ReplyDeleteI'm having very interesting information regarding Solar Pump suppliers in India

Very informative !!

ReplyDeleteHydraulic Pump Repairing Service Provider Delhi

ReplyDeleteHydraulic Pump Repairing in Delhi

Thanks for sharing

ReplyDeleteLooking to avail Hydraulic Power Unit in Singapore? If yes then IE group is the best place for you. just make a call on +65 6261 7938 to get best quotes for Hydraulic Power Unit in Singapore.

jyo094lcwi

ReplyDeletegolden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

supreme outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet